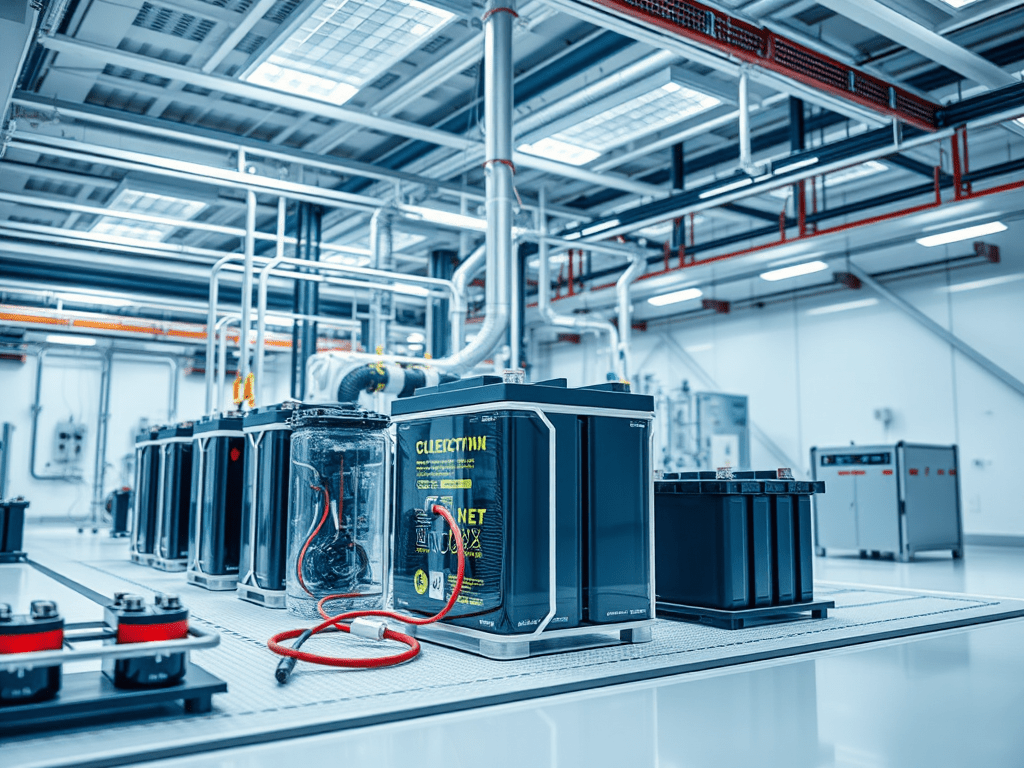

A newly launched European battery recycling consortium, valued at €3.137 million and led by the Production Engineering of E-Mobility (PEM) at RWTH Aachen University, is drawing attention not only for its strategic collaboration but also for the technological promise it represents. The consortium brings together a group of specialized industrial and academic partners, including Iondrive Limited (ASX: ION), Accurec Recycling GmbH, NEUMAN & ESSER Process Technology GmbH, and Constantia Patz GmbH, aiming to establish a sustainable and closed-loop battery recycling industry in Europe.

From a technology rating perspective, the initiative stands out due to its focus on scalable innovation and low environmental impact. Iondrive’s proprietary Deep Eutectic Solvent (DES) technology is at the heart of the project. Unlike traditional hydrometallurgical and pyrometallurgical methods, DES processing operates at low temperatures and eliminates the use of harsh acids, offering a cleaner and more energy-efficient route to recover key metals such as nickel, cobalt, lithium, and manganese from spent batteries. The recovered materials are then refined into precursor cathode active materials (pCAM) and integrated into new cell manufacturing processes.

The DES process has been rated highly for its adaptability and sustainability potential. It allows selective extraction of metals and has demonstrated laboratory efficiencies comparable to primary raw materials. The technology readiness level (TRL) is advancing quickly, as Iondrive completes construction of a pilot facility at the University of Adelaide, with commissioning expected in early 2026. The modular design of the facility allows it to be easily relocated to Europe, where it will be integrated into the consortium’s industrial network for validation and scaling.

According to Iondrive CEO Dr. Ebbe Dommisse, “The consortium offers a pathway to demonstrate to European OEMs that cells made from metals recycled using our DES process can perform on par with those made from virgin materials.” This claim is critical for the consortium’s objective: to prove that up to 80% recycled content can achieve equal electrochemical performance. If validated by the participating automotive OEMs, this would represent a significant step toward a European circular battery economy.

From an investment and technology evaluation standpoint, Iondrive’s participation also enhances its competitive position in Europe. The company benefits from substantial non-dilutive funding, with 60% of its European pilot costs covered (up to €398,000) and free access to feedstock and validation services. These elements reduce commercialization risk and accelerate market entry, both key metrics in technology maturity assessment.

Experts in sustainable technology rating would likely place the consortium’s combined approach at a mid-to-high TRL (6–7) stage—moving from pilot demonstration toward pre-commercial deployment. The integration with major European OEMs is expected to provide the necessary performance validation for scaling to full industrial operation.

In broader terms, the consortium embodies a shift in Europe’s industrial strategy—from resource extraction toward material circularity. By aligning academic research, industrial know-how, and policy support, it represents a model for how innovative cleantech solutions can transition from lab-scale development to market-ready systems. If successful, the project could serve as a benchmark for green technology rating agencies evaluating environmental impact, scalability, and long-term sustainability within the battery materials sector.

As Europe accelerates its energy transition, initiatives like this consortium could define the next standard in low-impact, high-efficiency metal recovery, positioning DES-based recycling as a best-in-class technology within the global circular economy framework.

Leave a comment